Nitrox Gas Blending Made Easy: Which Nitrox system should I buy?

When deciding which Nitrox System to purchase there are a couple things you might take into consideration to help you make the best decision:

You can use this spreadsheet to understand the types of costs associated with each of the different methods to make Nitrox. Nitrox Cost Breakdown Spreadhseet Here is an additional spreadsheet to help you understand what it costs to fill a SCUBA tank at your shop. Tank Fill Cost Spreadsheet EnviroDive Services has an inexpensive downloadable Gas Blender Manual that has a wealth of information about Nitrox. There are three major ways out there to make Nitrox. They are:

There are advantages and disadvantages to each of the systems, here’s a quick rundown of their strengths and weaknesses: |

|

Partial Pressure Blending:

Mixes pure oxygen directly into an empty and oxygen clean certified SCUBA tank, then topped off with with Oxygen Compatible Air (OCA) from banks to create desired oxygen mixture. Depending on the complexity of the blending station, you will spend a couple thousand dollars on the mixing panel and additional filtration system. Bottled oxygen needs to be obtained from your local gas Gas Distributor.

Advantages

- Lowest initial startup cost

- Able to mix any mixed gas percentage

Disadvantages

- Very tedious process – Substantial amount of labor, generally 20-30 min, to fill each SCUBA tank.

- SCUBA tanks and fill system need to be Oxygen Clean Certified – more expensive VIP process.

- Potentially dangerous if oil has been inadvertently admitted to SCUBA tank (diesel effect resulting in explosion)

- Unable to use all Oxygen in O2 Tank unless you have a Booster Pump. Usually send O2 tank back to Gas Distributor with ~400 psi.

- Accuracy of Nitrox mix is dependant on the proficiency of the person operating the fill station.

- Need to have readily available supply of Oxygen

Greg McLaughlin from Jack’s Diving Locker in Kailua-Kona, Hawaii, wrote a great partial pressure blending calculator for the iphone that will also work on your web browser. It works best on Firefox or Safari. http://iphone.somemore.com/mixer/

More information about the calculator is available at: http://iphone.somemore.com

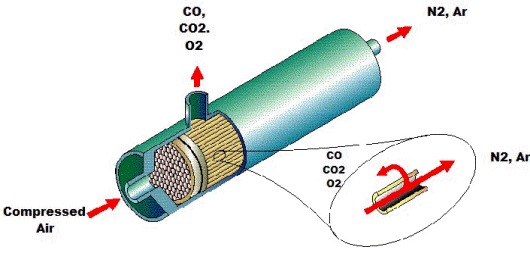

Nitrogen Separating Membrane:

This technology was initially developed by the welding industry to generate Nitrogen. It uses a low pressure air source (or a high pressure air source regulated to low pressure) to force heated air through a special membrane system. There are two outlets from the membrane: one for the nitrogen vent, and one for the permeate (enriched Oxygen mixture) that goes into your high pressure air compressor. There are a couple different variations on this design. The oxygen content is controlled by either adjusting the input pressure to the membrane or adjusting the nitrogen vent. The membrane is unstable initially until it reaches operating temperature (~30 min). Adjustments to the membrane input pressure or nitrogen vent typically take about a minute before their affects stabilize at the oxygen sensor at the inlet to the HP air compressor. The outlet of HP air compressor is either sent directly into SCUBA tanks or a Nitrox Bank. More information about nitrogen separating membranes is available at AirLiquide, and Air Products.

|

|

Advantages

- Requires no bottled oxygen, independence from oxygen distributors.

- Can safely make Nitrox up to 40%

- Scuba tanks and fill system do not need to be oxygen clean.

Disadvantages

- Expensive initial procurement cost – typically on the order of $15-20K for a system capable of delivering 36% Nitrox at 15CFM

- System is slow to start up and can be frustrating to operate – difficult to dial in desired oxygen mixture. The heated air fed to the membrane causes the chemical reaction in the oxygen sensor to speed up, significantly throwing off oxygen analyzer calibration.

- Additional costs (electricity/maintenance) associated with running low pressure air compressor to supply air to membrane.

- If HP air banks are used to provide input air pressure to membrane – there is an enormous amount of wasted HP air and associated HP compressor electricity and wear.

- If filters are not frequently changed, membrane can get clogged with dirt particles, requiring its replacement – expensive!

- Membrane is fragile and can be damaged due to carelessness, if over pressurized or not properly heated (making the tubes brittle), you can easily burst the small tubes inside, requiring the membrane to be replaced – expensive!

- Replacement membranes are expensive! If system the is equipped with a LP compressor, a replacement membrane represents about half the cost of the system. If the system uses a HP to LP regulator, the replacement membrane represents about two third’s the cost of the system. A replacement 6 foot membrane (used with 15CFM compressors) costs $8K.

- System should be constantly monitored during operation.

- Usually the highest cost per Nitrox SCUBA Tank.

Continuous Gas Blending with Nitrox Stik:

The Nitrox Stik continuous gas blender uses O2 tanks and a patented blending “Stik†to homogeneously mix air and pure oxygen at the inlet of a high-pressure air compressor. Placing the system on service involves isolating the system’s air storage bank, bleeding all the air out of the lines on the discharge side of the compressor (this reduces the time it takes to purge the air and replace it with Nitrox), and then while the compressor is running, placing the oxygen tank on service and throttling the oxygen supply to achieve the desired oxygen concentration. Continue bleeding the discharge of the air compressor until the system is purged and the oxygen analyzer monitoring the outlet of the compressor indicates the desired oxygen concentration. The air compressor, associated filters and air lines have now all been purged and he outlet of HP air compressor is either sent directly into SCUBA tanks or a Nitrox Bank. It typically takes between 5-10 minutes to place the system on service and start filling Nitrox SCUBA Tanks.

Advantages

- Moderate initial procurement cost – $2300 for the Nitrox Stik and an additional $2700-$3200 (depending on size of HP compressor) for the Nitrox Controller.

- Can Safely make Nitrox up to 40%.

- Scuba tanks and fill system do not need to be oxygen clean.

- Nitrox Controller allows operator to attend to other matters while filling Nitrox Tanks, reduces labor costs, increases accuracy of Nitrox Mix, and has additional safety features.

- Usually lowest cost per Nitrox SCUBA Tank by far when considering oxygen, labor and operating costs.

Disadvantages

- System should be constantly monitored during operation (unless Nitrox Controller is installed).

- Need to have readily available supply of Oxygen.

When taking everything into account, the Nitrox Stik with the Nitrox Controller usually makes the most sense.